Best Overview to Preventing Weld Undercut: Tips and Techniques

Best Overview to Preventing Weld Undercut: Tips and Techniques

Blog Article

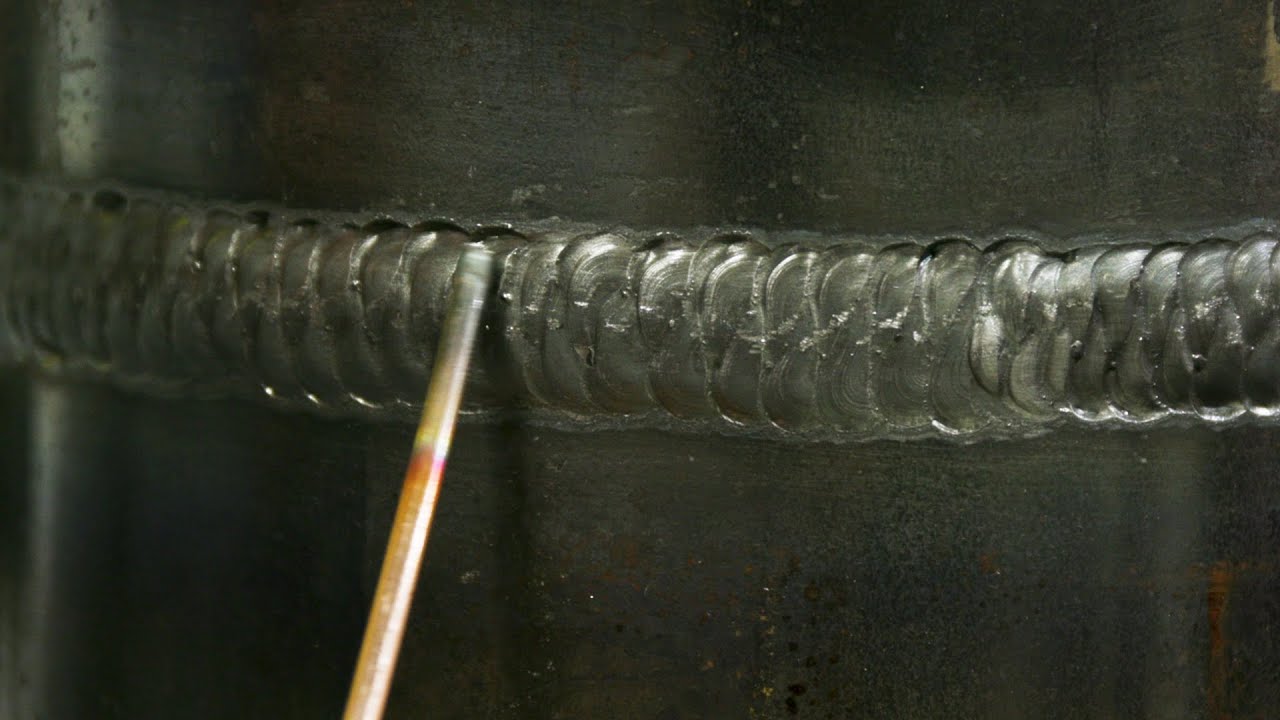

Mastering the Art of Welding: Just How to Avoid Undercut Welding Issues for Flawless Construction Outcomes

By understanding the root causes of undercut welding and executing efficient strategies to stop it, welders can elevate their craft to new levels of excellence. In the pursuit of flawless fabrication results, mastering the art of welding to avoid undercut issues is not just an ability yet a need for those striving for excellence in their job.

Recognizing Undercut Welding

To stop undercut welding, welders must ensure appropriate welding criteria, such as adjusting the present, voltage, traveling speed, and preserving the proper electrode angle. Additionally, utilizing the ideal welding technique for the certain joint arrangement is important. Utilizing weaving activities or backstepping techniques can assist make certain proper weld metal deposition and minimize the probability of undercut development. Regular examination of welds during and after the welding procedure is also important to catch any undercut very early and make needed changes to avoid further problems. Preventing weld undercut. By comprehending the reasons of undercut welding and applying safety nets, welders can accomplish high-quality, structurally sound welds.

Root Causes Of Undercut in Welding

Recognizing the factors that add to damage in welding is important for welders to generate high-quality, structurally sound welds. Poor welding current or inaccurate welding speed can likewise add to damage. Recognizing these causes and executing correct welding strategies can help avoid damaging concerns, making certain long lasting and solid welds.

Strategies to Prevent Undercutting

To alleviate the threat of damaging in welding, welders can use strategic welding techniques aimed at improving the high quality and stability of the weld joints. One reliable approach is to readjust the welding criteria, such as voltage, existing, and take a trip rate, to make certain correct warmth input and deposition. Keeping an ideal electrode angle and making certain regular traveling rate can additionally assist stop undercut. Furthermore, utilizing the right welding method for the certain joint setup, such as weave or stringer beads, can add to reducing damaging. Preventing weld undercut.

Using back-step welding techniques and regulating the weld bead profile can additionally help distribute warmth evenly and reduce the threat of undercut. Regular assessment of the weld joint throughout and after welding, as well as implementing high quality guarantee measures, can help in detecting and resolving damaging issues quickly.

Value of Correct Welding Parameters

Selecting and keeping suitable welding specifications is crucial for achieving successful welds with minimal problems. Welding criteria refer to variables such as voltage, current, travel speed, electrode angle, and protecting gas circulation price that straight affect the welding procedure. These criteria have to be carefully adjusted based on the sort of material being bonded, dig this its density, and the welding strategy used.

Correct welding criteria make certain the appropriate quantity of warmth is put on thaw the base metals and filler material consistently. If the parameters are set too expensive, it can lead to excessive warmth input, creating burn-through, distortion, or spatter. On the other hand, if the parameters are too reduced, insufficient combination, lack of infiltration, or damaging may occur.

Quality Control in Welding Workflow

Conclusion

In conclusion, understanding the art of welding requires a thorough understanding of undercut welding, its you could check here reasons, and techniques to prevent it. By making sure proper welding criteria and executing quality guarantee practices, perfect fabrication outcomes can be achieved. It is crucial for welders to regularly strive for excellence in their welding procedures to avoid undercut concerns and create high-quality welds.

Undercut welding, a typical defect in welding procedures, takes place when the weld metal does not properly fill up the groove and leaves a groove or depression along the welded joint.To protect against undercut welding, useful content welders must guarantee correct welding parameters, such as changing the existing, voltage, travel speed, and preserving the proper electrode angle. Inadequate welding present or wrong welding rate can additionally contribute to undercut.To alleviate the threat of damaging in welding, welders can employ tactical welding strategies aimed at improving the high quality and honesty of the weld joints.In verdict, mastering the art of welding needs a complete understanding of undercut welding, its reasons, and techniques to prevent it.

Report this page